BETWEEN ENERGY SAVING AND ECO-SUSTAINABILITY

New technologies for comfort and air quality in our homes: we talked about it with brothers Gianluca and Massimo Masiero, souls of Templari Srl, all-Italian excellence in heat pump heating and air conditioning systems.

The “smart home” is now a reality: the contemporary home is becoming smart thanks to the continuous supply of new technologies, with network-connected components that make it easy and straightforward to manage home environments.

“Houses are becoming more and more – and almost exclusively – electric, new homes are being built directly with heat pump heating and air conditioning systems, and if you add to these induction cookers and the electric car column, here is where the future will increasingly see independence from fossil fuels as a value, along – of course – with saving resources,” confirms Gianluca Masiero, technical manager of Templari Srl, a company based in Rubano (Padua) that in little more than a decade has established itself among the international excellences in heat pump design and production, plant management and air treatment systems.

“Right from the start, we identified air-water systems as a source of energy that would not create excessive environmental impact, that would be environmentally sustainable,” explains Massimo Masiero, Templari’s sales manager.

“Therefore, the idea was to design and implement a heat pump that was able to work without the aid of a boiler and without the aid of an electric heater.

To do this, innovative technologies have been introduced, with major investments in software and mechanics.

After the first years in which it was difficult to get the concept across that a heat pump could be able to replace the boiler, the market proved us right, and-luckily or by vision-we are now in the position not only of being among the few Italians to have certified the performance of the machine, but of representing its excellence at the European level as values obtained in tests.”

So let’s talk about the future in heating and air conditioning systems in homes and industrial buildings. The advantages of using this technology over a boiler are countless.

“If a heat pump works at a low temperature it can save up to 30-40% compared to a gas boiler,” Gianluca Masiero points out.

“To make it clear: the heat pump consumes 1 kW to yield 4 kW. Then if instead of absorbing it from the electric grid I use clean energy obtained from photovoltaic and wind power systems, or from my own photovoltaic system, then here the heat pump is totally environmentally sustainable, that is, it does not consume fossil energy even for the 20/25% share.

Notably, our machines also have superior performance compared to similar technologies produced by our competitors, performance that has been certified by the world’s most famous and authoritative body-the Swiss WPZ-which has placed us in first place worldwide for energy efficiency.”

Templar systems also stand out in terms of design, with machines that are increasingly aesthetically refined, but also for great versatility and ease of use, thanks to highly advanced software and hardware components.

“One element that distinguishes our systems is the operator panel, which is very simple and intuitive to use, and through the connection allows the system to be controlled remotely with a PC or smartphone,” Gianluca Masiero confirms.

“Customers also really like knowing that thanks to this technology we are able to connect and do remote supervision of the machine even if it is already installed in their home.

In fact, the heat pump is increasingly an integral part of a structured system that allows for more and more complete and total management of the environmental comfort of the whole house, a system that is easily controlled via monitor consisting of software, electronics and sensors that monitor humidity and stale air, and start the air handling unit when needed.

To this we add an energy optimizer that adjusts the operation of the machine with respect to atmospheric conditions and the energy production levels of the photovoltaic system, and actually halves consumption.”

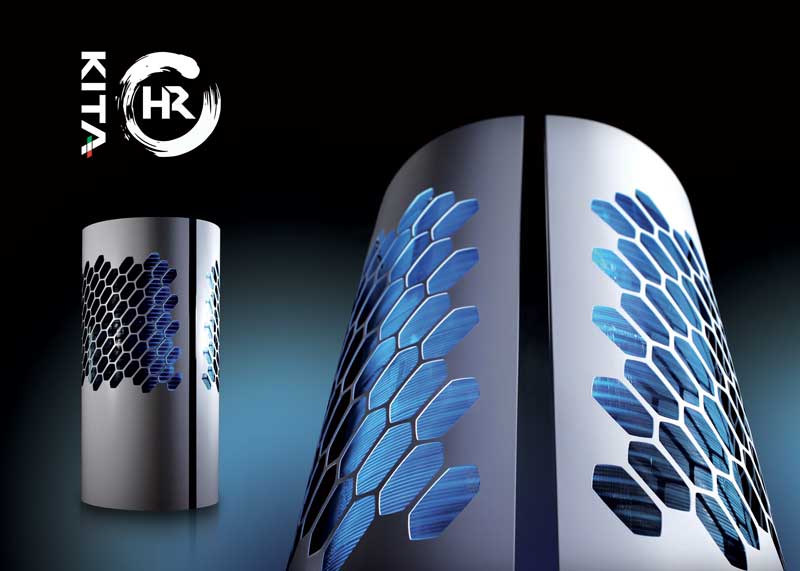

In addition to residential systems, Templari also aims to solve the industrial needs for winter heating and summer air conditioning of large indoor spaces, such as warehouses, production areas, warehouses and gyms, by designing Kita Air: an air-to-air heat pump that is innovative, easy to install and operate, and cost-effective (more).

Gianluca points out that one of KITA Air’s greatest innovations is to run the defrosting cycle only when it is needed.

Defrosting is the weak point of traditional heat pumps because it is a high expenditure of energy and because it wears out the compressor.

“That’s why we put effort and resources into it, until we came up with a fantastic solution that we decided to patent.” Templari’s achievements in its early years are a prerequisite for a bright future for the Padua-based company.

“Enthusiasm and confidence in the company’s potential on the part of our entire team, a group of young professionals with great expertise,” Massimo confirms.

“Today we produce more than a thousand machines a year, export them all over Europe, and our double-digit growth sets the stage for expanding our market to the rest of the world,” Massimo confirms. “It is a source of pride for us to be present even in economically strong and competitive countries such as Germany, Switzerland, and Austria, as well as in Poland, Russia, and Ukraine, where, due to their climates, our products become an almost compulsory choice due to their performance.

We will continue to offer very high quality and efficiency at a competitive price, with the intention of making a “premium” product mass market, including through increasing automation of the production process, a different mindset and approach.”

Source: Panorama